- Annual Financial Reporting Automation, amplifying efficiency, accuracy & profits

- Online store’s data Integration with SAP, Salesforce, Paypal, and PIMCore

- Bazaar Voice Integration for Agricultural Cooperative based Industry

- Booking Reservation Module for Leading Hospitality Company

- Role-Based Document and Apps Portal: Streamlining Access and Management with Azure

- Effective Workflow Approval and Document Management for Logistics Leader

- Increase in Real Time Media Transcript Generation by 7X, Reduced System Errors by 90% and Improved S

- Managing 500 million pageviews/month without a single downtime

- Automating Media Conversion and share to generate additional Revenue for Global Media Giant

- Seamless Sports Facility Booking System for Infrastructure Development Company

- Optimizing Exchange Server for better managed Email flow for Mining Company

- Improving End User Experience & Gamifying for leading Media & Broadcasting Company

- Helping Client to Increase Leads and Manage existing Accounts to generate Opportunities

- Provided Flexible Solution to Enhance User Experience, Manage Marketing and Customer Engagement

- Our solution helped in improving overall Website performance, Increase in Online Bookings & Sales

- Vital Lifesaving Information Solution for leading Canadian Healthcare Company

- Robust, Scalable and Cost-Effective Pimcore CMS solution for a Healthcare organisation/institute

- MS Dynamics CRM Solution to Increase Leads generation and add value to existing Accounts

- Kentico Implementation Helped Our Client in Improving User Experience, Increase in website traffic

- Improved Customer Engagement, Increased Website Performance & Search Experience Post Implementing

- Powerful API, Seamless Integrations, Intuitive and Flexible Content Management

- Innovative Pimcore Web Solution for Infrastructure Development Company

- Enhanced User-Experience, Easy to Maintain Document Management System with Workflows

- Flexible Data Model, Product Variations and User Friendly Configuration of Product Information

- Taxlinked Tokbox - International Online Tax Community based outskirts of Europe

- Powerful Data Migration Tools, Easily Maintainable Document Management System, User Friendly

- Classic Holidays - Australasia’s largest privately owned Resort

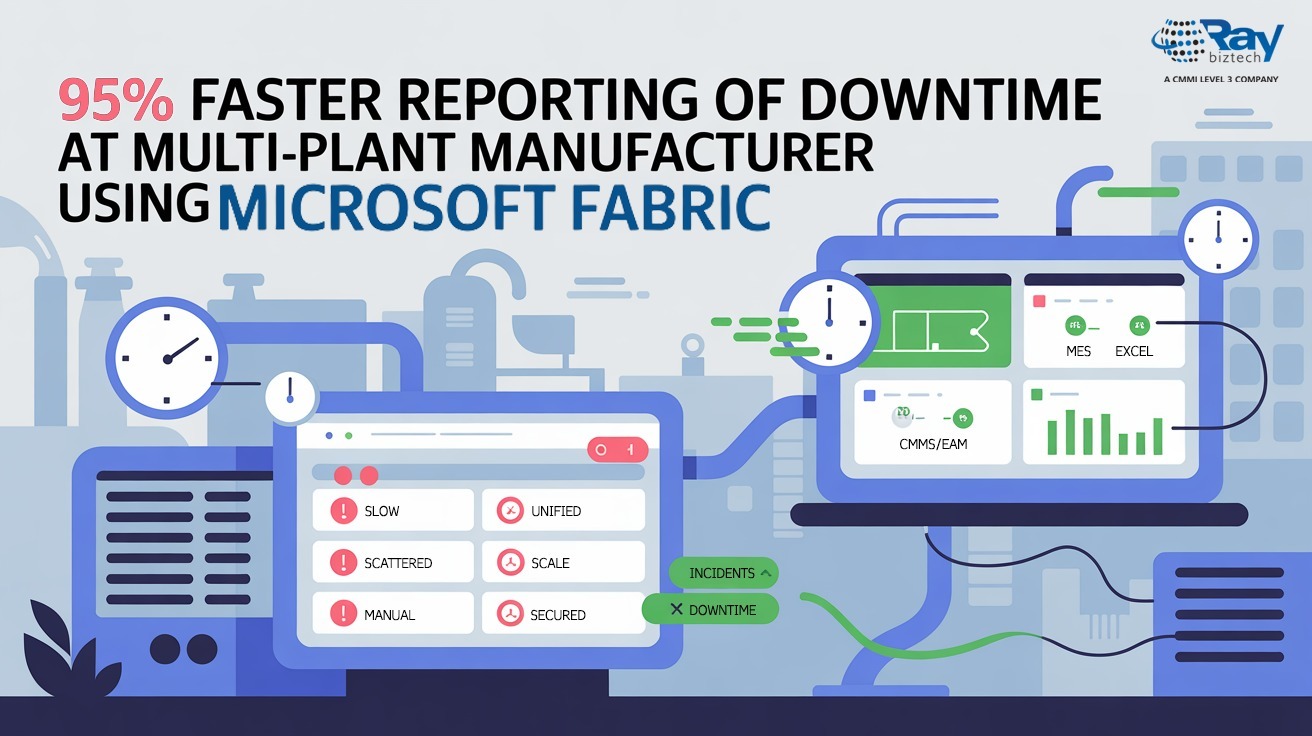

95% Faster Reporting of Downtime at Multi-Plant Manufacturer using Microsoft Fabric

Client Overview

A multi-plant manufacturer operating across North America needed faster, trustworthy visibility into equipment downtime and incidents. The client lacked real-time visibility into Asset Performance Intelligence, leaving them unable to predict equipment failures or standardize downtime tracking across North American plants.But, vital equipment health data was scattered across disconnected spreadsheets and legacy software, forcing teams to waste hours chasing numbers instead of fixing floor issues.

Project Summary

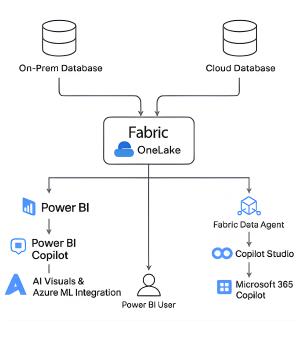

Ray Business Technologies unified incident and downtime data in Microsoft Fabric (OneLake) and delivered governed semantic models, role-based Power BI dashboards and a conversational Copilot layer. Leaders can now ask questions in plain language and get instant, decision-ready answers.

Eliminating Data Silos and High-Cost Inefficiencies

- Fragmented logs across CMMS/EAM, MES, and spreadsheets with inconsistent definitions

- Slow reporting cycles and manual reconciliations that delayed action

- Limited self-service, heavy reliance on IT report queues

- Low confidence in KPIs like downtime, availability, MTBF and incident rate

The Solution: Implemented Technical ROI of Microsoft Fabric

Ray Business Technologies replaced fragmented legacy workflows with a unified AI-driven data ecosystem. By leveraging the Microsoft Fabric architecture, we delivered a platform where technical efficiency translates directly into operational savings:Unified Data Foundation (OneLake & Data Factory)

- Centralized Source of Truth: We ingested disparate incident and downtime tables from CMMS/EAM and MES into a single OneLake environment, eliminating the "data tax" caused by siloed systems.

- Zero-Maintenance Ingestion: By utilizing Azure Data Factory for automated, scheduled loads, we reduced manual data handling, leading to a 90% reduction in reconciliation errors.

Business-Ready Semantics (The Metric Engine)

- Standardized Hierarchies: We developed a governed semantic layer that standardizes definitions across Plant → Line → Machine. This ensures 100% metric alignment, meaning a "downtime event" is defined identically in every facility.

- Drill-Down Granularity: Curated Power BI models now allow for instant variance analysis by shift, product, and cause code, transforming raw data into actionable root-cause insights.

Conversational Analytics (Power BI Copilot)

- Democratized Intelligence: We enabled Power BI Copilot, allowing floor managers and executives to bypass IT queues and ask questions in plain language.

- Self-Service ROI: This "Ask-the-Data" capability reduced ad-hoc BI ticket volume by 60–80%, freeing IT resources for higher-value engineering tasks.

Governance & Secure Scale

- Role-Based Access Control (RBAC): Implemented enterprise-grade security and lineage tracking to ensure sensitive production data is only accessible to authorized personnel.

- Automated Refresh Policies: Optimized data refresh cycles to move the plant toward near real-time visibility, reducing report preparation time from 6 hours to less than 1 minute.

Hard-Dollar Savings & Workforce Optimization

- Labor Recovery: Report preparation time crashed from 6 hours to less than 1 minute (95% faster).

- Overtime Control: Real-time visibility led to a 10–15% reduction in overtime costs.

- IT Efficiency: Ad-hoc BI ticket volume dropped by 60–80%.

- Rapid Payback: Full ROI achieved within a 3–6 month window.

| Microsoft Fabric Technical Component | Operational/Financial Outcome | Metric of Success |

| OneLake & Data Factory: Unified ingestion of CMMS, MES and spreadsheet data. | Elimination of "Data Silos": Provides a single source of truth, ending manual data reconciliation. | 90% Reduction in reconciliation errors. |

| Governed Semantic Layer: Standardized metric definitions for plant, line and machine analysis. | Process Optimization: Enables root-cause analysis of unplanned stops and scrap. | 20% Fewer unplanned stops. |

| Power BI Copilot & Q&A: Natural language conversational insights layer. | Labor Efficiency: Drastic reduction in time spent by staff on manual report preparation. | 95% Time Saved (from 6 hrs to <1 min). |

| DirectLake Connectivity: High-performance analytics without data movement or duplication. | Cost Containment: Real-time visibility allows for immediate action against production variances. | 10–15% Reduction in overtime costs. |

| Self-Service Analytics: Role-based dashboards with drill-down views by cause code. | IT Resource Optimization: Shifts the burden of ad-hoc reporting from IT back to the business users. | 60–80% Lower BI support ticket volume. |

The Roadmap to Industry 4.0 by achieving Operational Excellence

With a clean semantic layer and conversational analytics, the manufacturer now runs a continuous improvement loop: weekly KPI reviews, targeted actions against the top downtime causes, and monthly value checkpoints. Next steps include incremental refresh for near real- time views, predictive maintenance models, and expanding the blueprint to quality, energy and procurement turning insights into sustained operational gains.| Metric Category | Key Performance Indicator (KPI) | Impact Achievement |

| Operational Efficiency | Unplanned Stops | 20% Reduction |

| Equipment Reliability | Mean Time Between Failures (MTBF) | 10–15% Increase |

| Maintenance Speed | Mean Time to Repair (MTTR) | 15–25% Faster |

| Production Velocity | Line Cycle Time | 5–10% Reduction |

| Quality & Waste | Scrap from Repeat Incidents | 8–12% Reduction |

| Supply Chain | Freight Spend (Expedited Shipping) | 20–30% Savings |

About Ray Business Technologies

Ray Business Technologies is a Global Information Technology (IT) Services and Solutions company. We are a CMMI Level 3 company, providing cutting-edge IT Solutions to Enterprises worldwide, enabling them to utilize available resources effectively and manage the operations. Our excellent team of Technology Professionals work with enterprise clients in North America, Latin America, Australia, Europe, Middle East and Asia.www.raybiztech.com

We use cookies to provide the best possible browsing experience to you. By continuing to use our website, you agree to our Cookie Policy